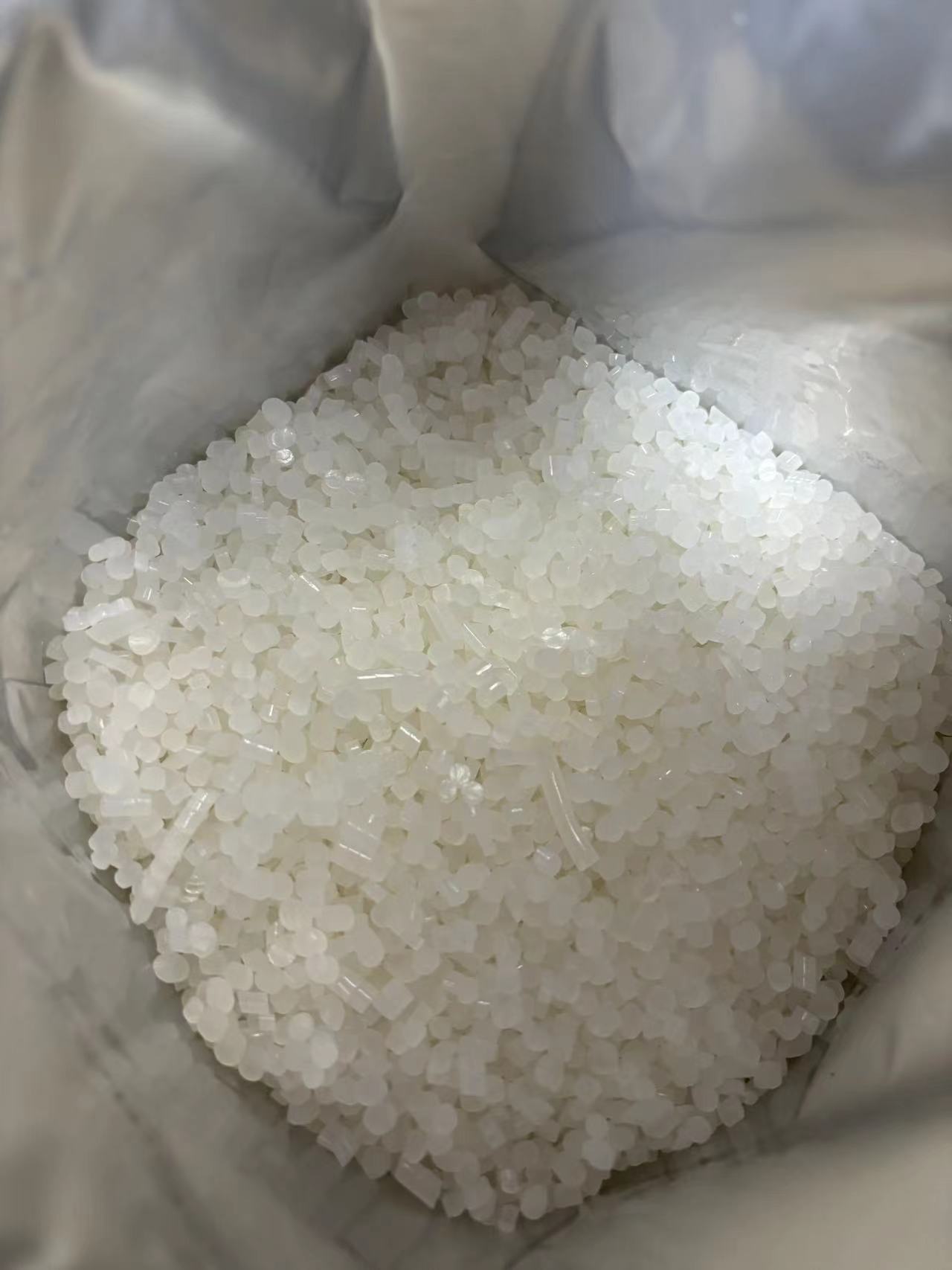

Cov khoom siv rov ua dua tshiab TPU / yas granules / TPU resin uas tsis muaj carbon ntau

Txog TPU

TPU rov ua dua tshiabmuaj ntau yamcov txiaj ntsig raws li nram no:

1.Kev phooj ywg ib puag ncigTPU rov ua dua tshiab yog ua los ntawm cov khoom siv rov ua dua tshiab, uas pab txo cov khib nyiab thiab kev siv cov khoom siv tshiab. Nws pab txhawb rau ib puag ncig uas ruaj khov dua los ntawm kev hloov cov khib nyiab TPU ntawm cov chaw pov tseg thiab txo qhov xav tau kev rho tawm cov khoom siv raw.

2.Kev siv nyiaj zooKev siv TPU rov ua dua tshiab yuav raug nqi ntau dua li siv TPU tshiab. Vim tias cov txheej txheem rov ua dua tshiab siv cov khoom siv uas twb muaj lawm, nws feem ntau xav tau lub zog tsawg dua thiab cov peev txheej tsawg dua piv rau kev tsim TPU los ntawm kos, ua rau cov nqi tsim khoom qis dua.

3.Cov Khoom Siv Kho Tshuab Zoo: TPU rov ua dua tshiab tuaj yeem khaws cia ntau yam khoom siv zoo ntawm TPU tshiab, xws li lub zog tensile siab, elasticity zoo, thiab tiv taus kev sib txhuam zoo heev. Cov yam ntxwv no ua rau nws haum rau ntau yam kev siv uas xav tau kev ruaj khov thiab kev ua tau zoo.

4.Kev Tiv Thaiv TshuajNws muaj kev tiv taus zoo rau ntau yam tshuaj lom neeg, roj, thiab cov kuab tshuaj. Cov khoom no ua kom ntseeg tau tias TPU rov ua dua tshiab tuaj yeem tswj tau nws txoj kev ncaj ncees thiab kev ua tau zoo hauv qhov chaw ib puag ncig hnyav thiab thaum raug rau ntau yam tshuaj sib txawv, nthuav dav nws daim ntawv thov.

5.Kev Ruaj Ntseg Thermal: TPU rov ua dua tshiab muaj kev ruaj khov zoo, uas txhais tau tias nws tuaj yeem tiv taus qee qhov kub thiab txias yam tsis muaj kev hloov pauv tseem ceeb hauv nws cov khoom siv lub cev thiab tshuab. Qhov no tso cai rau nws siv rau hauv cov ntawv thov uas xav tau kev tiv thaiv cua sov.

6.Kev siv tau ntau yamIb yam li TPU tshiab, TPU rov ua dua tshiab muaj ntau yam siv tau thiab tuaj yeem ua tiav rau ntau hom thiab cov khoom los ntawm ntau txoj kev tsim khoom, xws li kev txhaj tshuaj molding, extrusion, thiab blow molding. Nws tuaj yeem hloov kho kom tau raws li cov kev xav tau tshwj xeeb ntawm ntau yam lag luam thiab daim ntawv thov.

7.Txo Cov Pa roj carbon FootprintKev siv TPU rov ua dua tshiab pab txo cov pa roj carbon uas cuam tshuam nrog kev tsim khoom TPU. Los ntawm kev rov ua dua tshiab thiab siv cov ntaub ntawv dua tshiab, cov pa roj av uas ua rau lub tsev cog khoom puas tsuaj thaum lub sijhawm tsim khoom raug txo qis, uas yog qhov zoo rau kev tawm tsam kev hloov pauv huab cua.

Daim Ntawv Thov

Daim Ntawv Thov: Kev Lag Luam Khau,Kev Lag Luam Tsheb,Kev Lag Luam Ntim Khoom,Kev Lag Luam Textile,Kev Kho Mob,Cov Ntawv Thov Kev Lag Luam,3D luam tawm

Cov Kev Cai

Cov nqi saum toj no tau qhia ua cov nqi ib txwm muaj thiab yuav tsum tsis txhob siv ua cov lus qhia.

| Qib | Tshwj xeeb Lub ntiajteb txawj nqus | Qhov nyuaj | Tensile Lub zog | Qhov kawg Kev ntev | Modulus | Kua muag Lub zog |

| 单位 | g/cm3 | ntug dej A/D | MPa | % | MPa | KN/hli |

| R85 | 1.2 | 87 | 26 | 600 | 7 | 95 |

| R90 | 1.2 | 93 | 28 | 550 | 9 | 100 |

| L85 | 1.17 | 87 | 20 | 400 | 5 | 80 |

| L90 | 1.18 | 93 | 20 | 500 | 6 | 85 |

Pob khoom

25KG/hnab, 1000KG/pallet los yog 1500KG/pallet, ua tiav lawmyaspallet

Kev Tswj thiab Kev Khaws Cia

1. Tsis txhob ua pa cov pa luam yeeb thiab cov pa dej uas ua los ntawm cov khoom siv cua sov

2. Cov khoom siv kho tshuab ua rau muaj hmoov av. Tsis txhob ua pa plua plav.

3. Siv cov txheej txheem av kom raug thaum tuav cov khoom no kom tsis txhob muaj cov nqi hluav taws xob electrostatic

4. Cov khoom me me hauv pem teb yuav nplua thiab ua rau ntog

Cov lus qhia txog kev khaws cia: Yuav kom cov khoom zoo, khaws cia rau qhov chaw txias thiab qhuav. Khaws cia rau hauv lub thawv kaw ruaj ruaj.

Cov Ntawv Pov Thawj