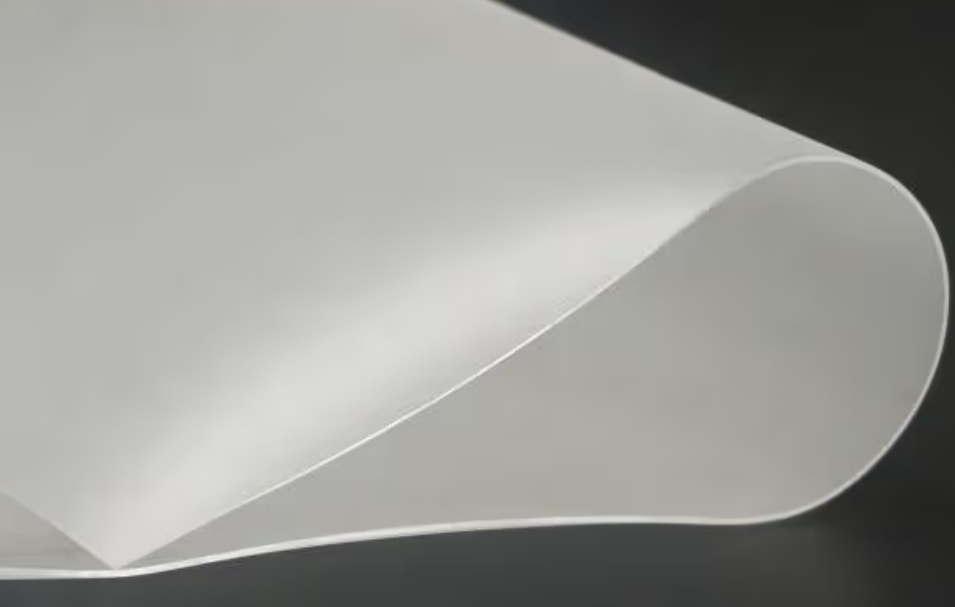

TPU zaj duab xis, ua cov khoom siv polymer ua tau zoo, ua lub luag haujlwm tseem ceeb hauv ntau qhov chaw vim nws cov khoom siv lub cev thiab tshuaj lom neeg tshwj xeeb. Tsab xov xwm no yuav

nkag siab txog cov ntaub ntawv sib xyaw, cov txheej txheem tsim khoom, cov yam ntxwv, thiab cov ntawv thov ntawmTPU zaj duab xis, coj koj mus ncig ua si kom txaus siab rau qhov kev zoo nkauj ntawm cov khoom siv no.

1. Cov ntaub ntawv sib xyaw ntawm TPU zaj duab xis:

Zaj duab xis TPU, tseem hu ua thermoplastic polyurethane zaj duab xis, yog cov khoom siv zaj duab xis nyias ua los ntawm polyurethane ua lub substrate los ntawm cov txheej txheem ua tiav tshwj xeeb. Polyurethane yog ib qho

polymer tsim los ntawm cov tshuaj tiv thaiv ntawm polyols thiab isocyanates, uas muaj kev tiv thaiv zoo heev, elasticity, thiab tshuaj lom neeg tsis kam. Yuav kom txhim kho nws cov kev ua tau zoo,

Cov khoom siv ntxiv xws li cov tshuaj antioxidants thiab UV absorbers kuj tseem raug ntxiv thaum lub sijhawm tsim cov yeeb yaj kiab TPU.

2. Cov txheej txheem ntau lawm:

Cov txheej txheem tsim khoom ntawmTPU zaj duab xiszoo thiab nyuaj, feem ntau suav nrog cov kauj ruam hauv qab no:

Kev sib sau ua ke: Ua ntej, nyob rau hauv qhov kev ua ntawm cov catalyst, polyols thiab isocyanates dhau los ua cov tshuaj tiv thaiv polymerization los tsim cov polyurethane prepolymers.

Yaj extrusion: Sov lub prepolymer rau lub xeev molten thiab tom qab ntawd extrude nws mus rau hauv ib zaj duab xis los ntawm lub taub hau extruder.

Txias thiab ua kom zoo nkauj: Cov yeeb yaj kiab extruded molten yog txias sai los ntawm lub tshuab cua txias kom khov thiab tsim.

Kev ua tiav tom qab: suav nrog kev txiav, winding thiab lwm yam kauj ruam, kom thaum kawg tau txais zaj duab xis TPU tiav.

3. Cov yam ntxwv:

Cov yam ntxwv ntawm TPU zaj duab xis yog lub hauv paus rau nws daim ntawv thov dav dav, feem ntau pom tseeb hauv cov hauv qab no:

Lub zog siab thiab elasticity: TPU zaj duab xis muaj lub zog tensile siab thiab muaj peev xwm rov qab tau elastic zoo, thiab tuaj yeem tiv taus cov zog sab nraud loj yam tsis muaj kev hloov pauv.

Hnav tsis kam: Qhov tawv ntawm qhov chaw yog qhov nruab nrab, nrog kev hnav tsis kam zoo, tsim nyog rau ntau qhov chaw ib puag ncig hnyav.

Kev tiv thaiv kub: muaj peev xwm tswj tau qhov ruaj khov hauv qhov kub thiab txias ntawm -40 ℃ txog 120 ℃.

Kev tiv thaiv tshuaj lom neeg: Nws muaj kev tiv thaiv zoo rau feem ntau cov tshuaj lom neeg thiab tsis yooj yim xeb.

Cov dej noo permeability: Nws muaj qee qib ntawm cov dej noo permeability thiab tuaj yeem siv rau hauv cov xwm txheej uas xav tau kev ua pa.

4, Daim Ntawv Thov

Vim nws qhov kev ua tau zoo heev, TPU zaj duab xis tau siv dav hauv ntau qhov chaw, suav nrog tab sis tsis txwv rau:

Kev lag luam khaub ncaws: Ua ib daim ntaub rau khaub ncaws, nws muab ib txheej tiv thaiv uas sib dua, tsis muaj dej, thiab ua pa tau.

Kev Kho Mob: Cov ntaub ntawv sab nraud xws li cov khaub ncaws phais, cov khaub ncaws tiv thaiv, thiab lwm yam yog siv los ua cov khoom siv kho mob.

Cov khoom siv kis las: siv los tsim cov khau kis las, hnab, thiab lwm yam khoom siv kis las, muab kev ruaj khov thiab xis nyob.

Kev lag luam tsheb: Ua ib yam khoom siv kho kom zoo nkauj sab hauv, nws tuaj yeem txhim kho qhov xis nyob thiab kev zoo nkauj ntawm lub tsheb ib puag ncig.

Kev tsim kho vaj tse: siv rau cov ntaub ntawv ru tsev, cov txheej dej tsis nkag, thiab lwm yam, los txhim kho kev tiv thaiv huab cua thiab kev siv hluav taws xob ntawm cov tsev.

Hauv kev xaus lus, ua ib yam khoom siv ntau yam, zaj duab xis TPU tau siv ntau dua thiab ntau dua hauv zej zog niaj hnub no. Nws cov ntaub ntawv sib xyaw yog qhov tshwj xeeb, cov txheej txheem tsim khoom

yog kev nce qib, thiab cov yam ntxwv ntawm cov khoom muaj ntau yam. Zaj duab xis TPU, nrog nws cov txiaj ntsig tshwj xeeb, tau ua pov thawj tias muaj txiaj ntsig tsis muaj qhov hloov pauv tau hauv ob qho tib si lub neej txhua hnub thiab cov teb thev naus laus zis siab.

Lub sijhawm tshaj tawm: Cuaj hlis-26-2024